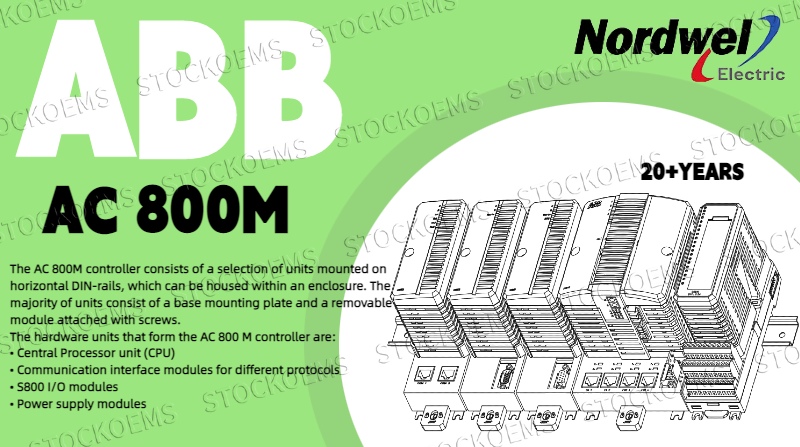

ABB AC 800M Series: Powerful Scalability in Communication and I/O Systems

The ABB AC 800M Series boasts powerful expandability in communication and I/O systems. Communication and input/output (I/O) capabilities are the lifeblood of modern controllers, and the ABB AC 800M series excels in this area. Its communication capabilities are greatly enhanced through the Communication Expansion Bus (CEX-Bus), allowing a single controller to connect to up to 12 communication units. This facilitates easy integration with various fieldbus networks, enabling seamless data exchange with upper-level management systems and horizontal devices. At the I/O level, the AC 800M's core advantage lies in its deep integration with the S800 I/O system. As a distributed, modular system, the S800 I/O connects to the controller via PROFIBUS-DP or direct Modulebus, supporting expansion to dozens of I/O modules. It allows for fully redundant configurations, including communication and I/O module levels, meeting the stringent high availability requirements of critical processes. The modular I/O units support hot-swapping, greatly facilitating online maintenance and system upgrades, and reducing unplanned downtime. This powerful, flexibly configurable communication and I/O expansion capability enables the AC 800M series to accurately and reliably connect and manage thousands of field signal points.