Introduction

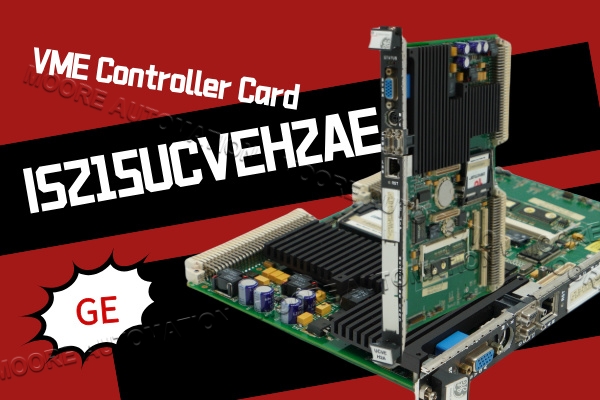

Overview of H2 VME Control Board

System fault diagnosis: Built-in recognition capability for 98 fault codes

Core Features of IS215UCVEH2A

Critical Role in Turbine Control

Integration with Mark VI/Mark VIe Systems

Application Value Analysis

Conclusion

Operation and maintenance strategy: Establish regular preventive inspection system