Bently Nevada 3500/22M: Unveiling the Power of Transient Data Interface

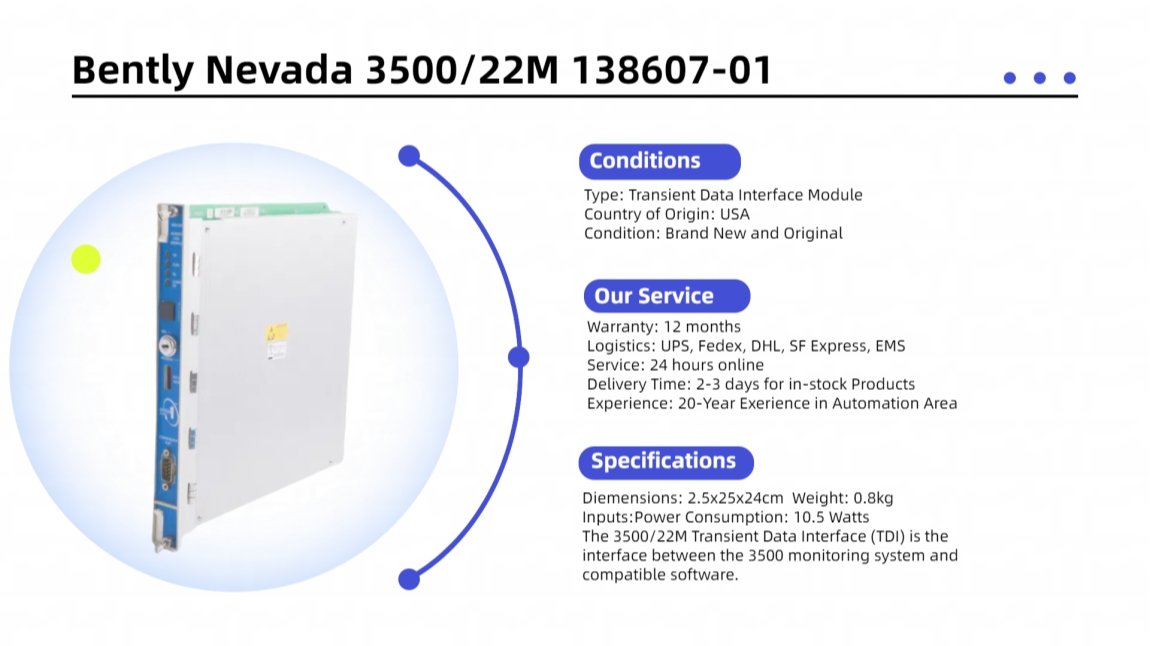

The Bently Nevada 3500/22M 138607-01 is a sophisticated data acquisition tool designed to monitor and capture transient events in rotating machinery. This module is a critical part of the 3500 Series machinery monitoring system, providing accurate measurements of vibration, pressure, and other key parameters. What sets it apart is its ability to record transient data, allowing users to track sudden changes in equipment performance that could indicate early signs of failure.

By integrating this module with other Bently Nevada products, companies can enjoy a more comprehensive machinery management system, ensuring that their equipment is operating at peak efficiency. This can help identify potential issues before they escalate into major failures, reducing maintenance costs and downtime. The 3500/22M module is compatible with a range of sensors and is an essential component for industries that rely on continuous operation, such as power generation, manufacturing, and oil and gas.

The 3500/22M module is packed with features that make it a standout solution for monitoring and analyzing transient data:

Real-Time Data Capture: It provides real-time analysis of transient events, helping operators detect anomalies that might be missed with conventional monitoring tools.

Wide Compatibility: This module is designed to work with a variety of sensors and transducers, making it versatile and easy to integrate into existing systems.

Enhanced Diagnostic Capabilities: With its ability to detect and log transient conditions, it provides better diagnostic insights into the root cause of performance issues, aiding in quicker repairs and reducing downtime.

Reliability and Durability: Built to withstand harsh industrial environments, the 3500/22M is highly durable, ensuring long-term performance even in challenging conditions.

The 3500/22M allows for superior data analysis and contributes significantly to the reliability and longevity of critical industrial assets. It’s not just about identifying problems—it’s about preventing them before they occur, which saves time, money, and resources.

In the realm of industrial automation and equipment monitoring, precise data analysis is essential to maximize performance and minimize downtime. The Bently Nevada 3500/22M 138607-01 Transient Data Interface Module offers a significant leap in this area by providing real-time insights into machinery performance. This cutting-edge technology ensures that operators can respond promptly to transient conditions, preventing equipment failure and improving overall reliability. In this article, we will explore the features, benefits, and applications of the 3500/22M module in industrial settings.

If you need more products welcome to contact us ! Email :sales3@mooreplc.com

More --》》》Bently Nevada 3300/20-02-01-02-00-00 Bently Nevada 330130-080-00-00 Bently Nevada 3300/16 XY/GAP Bently Nevada 3500/45